For decades, ordering a sandwich at places like Subway or Jersey Mike’s has been a familiar ritual. Customers step up to the counter, choose their bread, point to toppings, and watch a sandwich come together by hand. It’s a routine so ingrained in daily life that it feels timeless. Yet, beneath this simplicity, a quiet transformation is underway. Advances in artificial intelligence, robotics, and automation are reshaping even this everyday experience, opening the door to a new kind of sandwich shop.

This vision is captured in the idea known as the Robotic Sandwich, a term that dates back to the registration of the domain RoboticSandwich.com on October 31, 2018. The concept was imagined years ahead of widespread adoption, at a time when food robotics was still largely experimental. While the industry remains in its infancy, the groundwork laid by this early thinking is now beginning to align with real-world technological capabilities.

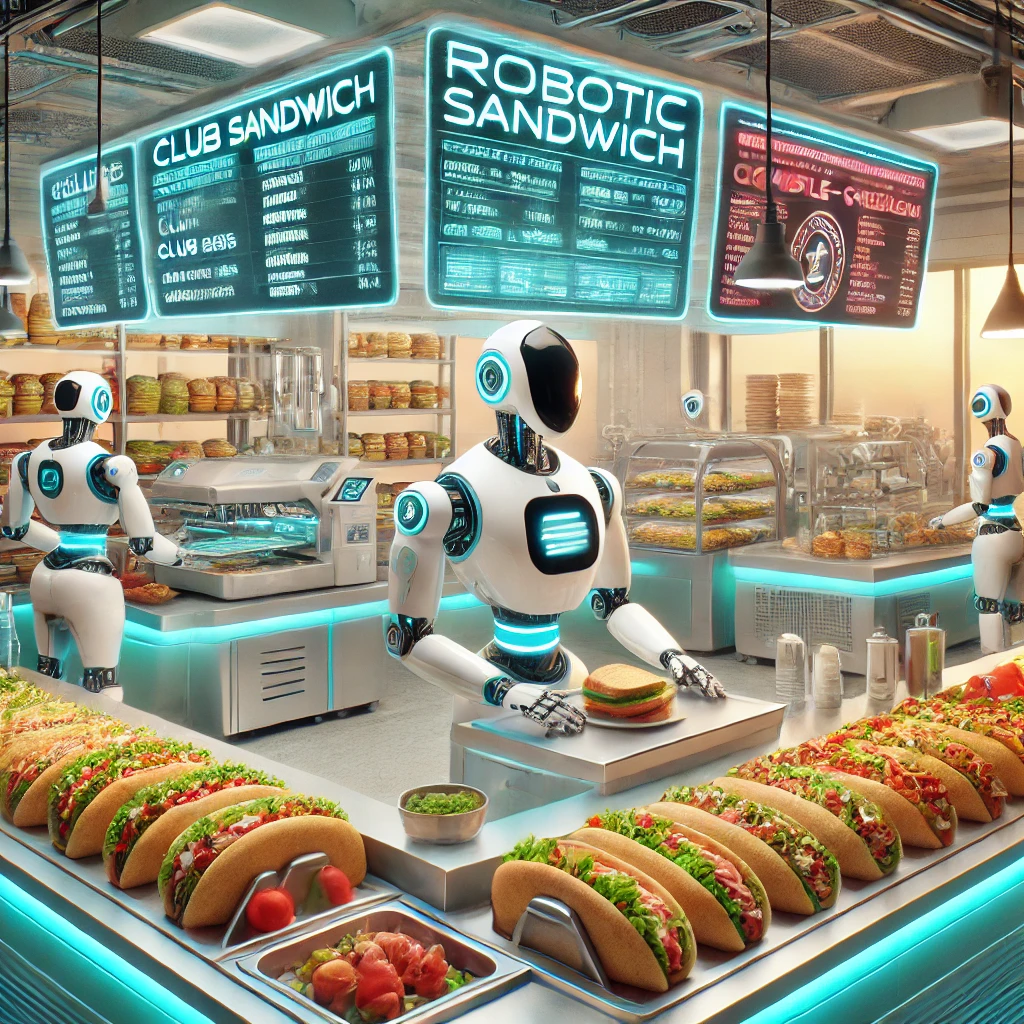

At its core, the robotic sandwich model is remarkably simple. Store owners prepare and arrange fresh ingredients—bread, meats, vegetables, cheeses, and sauces—on organized stations. From there, robots take over. Using sensors, software, and precise mechanical movements, they slice, layer, toast, assemble, and wrap each sandwich with speed and accuracy. Every step is guided by data, ensuring consistency and repeatable quality from order to order.

This automation does not come at the cost of variety. Robotic systems can produce an impressive range of sandwiches, from classic club sandwiches and Italian subs to Philly cheesesteaks, Chipotle-style wraps, and hearty beef or chicken creations. Breakfast options with eggs, ham, and cheese are also easily handled. Recipes can be adjusted digitally, allowing customers to customize portion sizes, ingredients, and combinations while still receiving a sandwich that tastes exactly as expected.

One of the most compelling advantages of robotic sandwich-making is efficiency. Robots do not fatigue, require breaks, or struggle during rush hours. They can operate continuously, helping reduce long lines and improve service speed during peak times. For store owners facing labor shortages or rising wages, automation offers a way to maintain productivity while keeping operations predictable and scalable.

Beyond efficiency, consistency and hygiene play a major role in the appeal of robotic kitchens. Robots follow exact measurements and standardized procedures, delivering the same sandwich every time a customer orders. With reduced direct human contact, the risk of food contamination can also be lowered—an increasingly important consideration for health-conscious consumers and in times of public health concern.

Still, this future is not without its challenges. Robotic systems require significant upfront investment, along with ongoing maintenance and software updates. For small or independent shop owners, these costs can be a major barrier. Additionally, robots lack the human element—casual conversations, personal recommendations, and the sense of familiarity that many customers value in a local sandwich shop.

Ultimately, the rise of the robotic sandwich represents both innovation and tension. Automation promises speed, precision, and consistency, but it also raises questions about cost, employment, and customer experience. As technology continues to evolve, the most successful sandwich shops of the future may strike a balance—using robots to handle repetitive, technical tasks while humans focus on creativity, hospitality, and connection.